Araştırma geliştirme yazı alanı

Within the framework of our R&D structure, we employ research

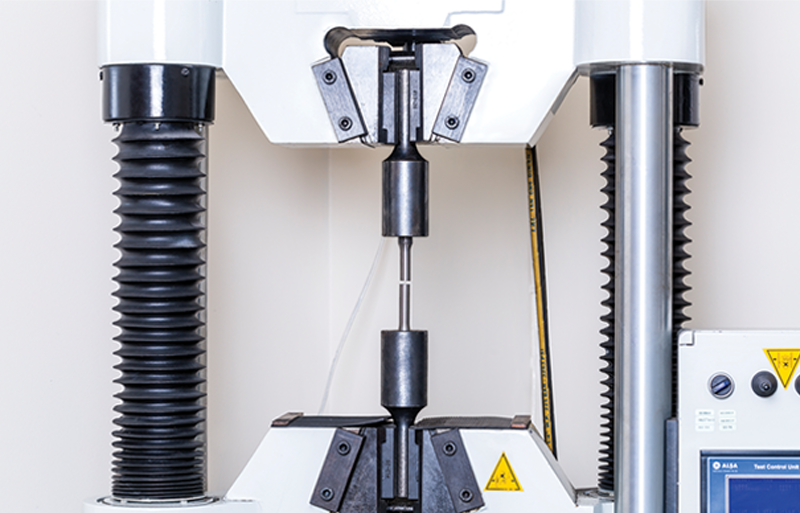

personnel with expertise in various specialized fields. Rolling

mill rolls, which operate under extremely demanding conditions,

are expected to possess characteristics such as high pass life,

mechanical strength, ease of machining, and high thermal

resistance.

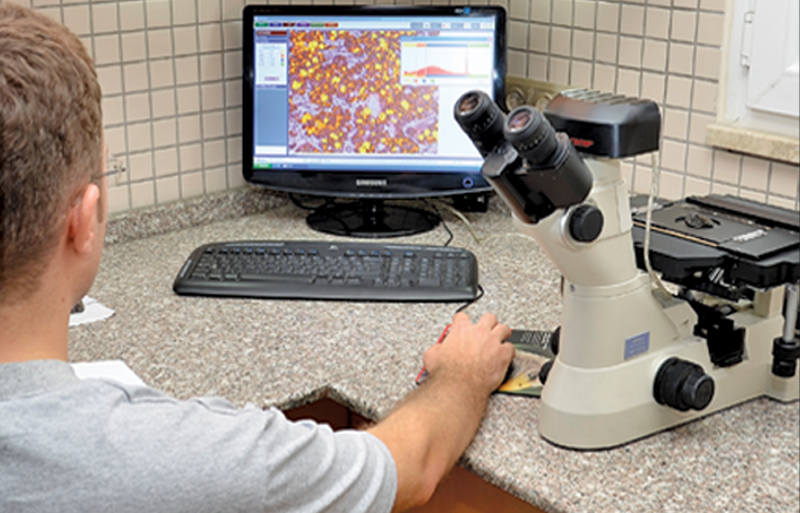

Since 2008, we have continued our product development projects

tailored to the specific requirements of our customers, who

operate under a wide range of applications and parameters.

In this context, we have developed Low-Carbon Alloy Steel,

next-generation Adamite, and Spheroidal Graphite

rolls—particularly for Blum, Rail, and Profile Mills. Some of

these innovations include ARSTEEL Maxima, ARMITE GT, ARMITE GQ,

and ARFIN Maxima.

Alloy steel rolls are preferred in heavy-duty mills such as block mills or those drawing billets from ingots or blooms, thanks to their high mechanical strength and acceptable wear resistance.

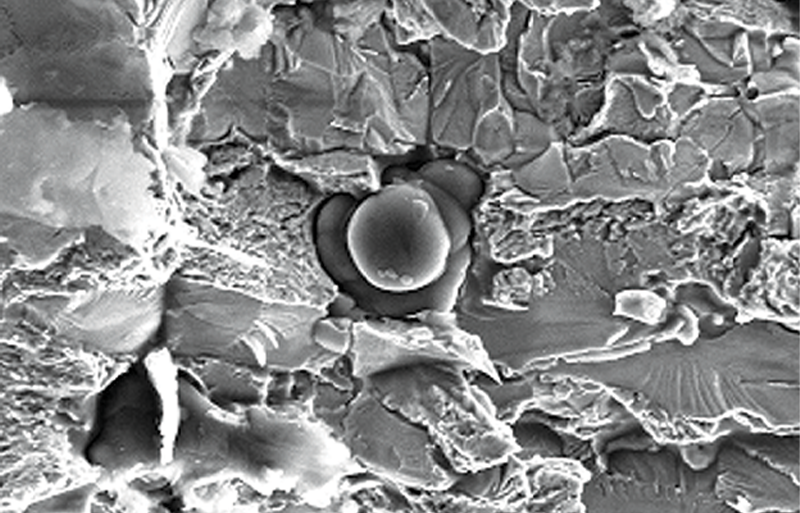

ARMITE GQ belongs metallurgically to the hypereutectoid steel group. Through normalization and quenching processes, a hardness increase of 5–7 HRC is achieved. This increase in hardness significantly enhances roll performance. It is an advanced R&D-developed product.

It belongs to the Adamite group; however, thanks to its modified alloy composition, graphite particles form within the structure. This enhances thermal conductivity and provides resistance against cracking. The hardness exceeds 65 SHC. Graphite minimizes wear by reducing friction.

With its bainitic and martensitic structure, it offers superior wear resistance. A low-temperature tempering process reduces transformation stresses. Mechanical strength and fracture toughness increase by 50–80%. It delivers high performance in finishing stands.